Ring Main system

In Stock

Compare

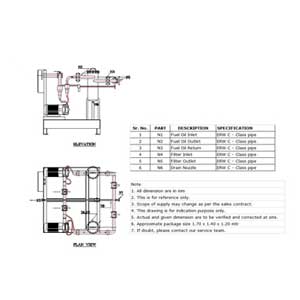

- To achieve complete combustion, it is necessary to get good atomization. For the oil pressure atomization, it depends upon oil viscosity and other properties of the fuel oil used. As discussed above, to get good atomization of the available FO, it is to be heated up to 130 Deg.C (for heavy oil, maximum viscosity in accordance with DIN 51603 is 450 mm 2/s or450 cSt at a temperature of 50 deg.C. From the graph, which shows the viscosity

- it can be seen that heavy fuel oil S remains pumpable up to value of 500 to 750 mm2/s or cSt. Since you are using pressure jet, oil return type atomization burner system, viscosity needed is 15 to 20 cSt at the nozzle tip and this can only be achieved by heating up to 130Deg.C and heating type nozzle rod in burner.

- From the above data it is necessary that furnace oil must be heated up to about 50 Deg.C, to make it pumpable, and to approx 130 Deg.C to allow pressure atomization. As explained above, to facilitate heating up to 130 Deg.C and to suppress the boiling point of water (100 Deg. C at one bar), the oil should be supplied at 46 Kg/ cm2 at the in let of fuel oil pump.

- This will avoid the vaporization of water content in the oil and low boilers in the furnace oil and in turn safeguard the fuel pump from cavitation problem and ensure proper operation of the burner system.

Your custom content goes here. You can add the content for individual product

Reviews

There are no reviews yet.