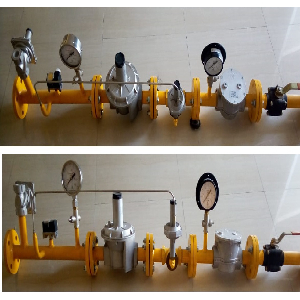

Fuel Firing Apparatus and Gas Train – Natural Gas

A typical fuel train has several components, each with a specific purpose which is

briefly explained below.

- Manual shut-off valve (MSOV) – the purpose of this valve is to shut off the fuel

supply so that maintenance or replacement of the fuel train may be done.

- Gas pressure regulator (PRV) – its purpose is to maintain the fuel at a constant

pressure as recommended by the burner manufacturer.

- Gas Filter – the function is to prevent foreign particle and extraneous impurities

entering Gas Pressure Regulator.

- Low pressure gas switch – senses a low pressure in the range where the burner

cannot properly operate. This switch must be equipped with safety lock-out

requiring manual reset. This tells the operator to check the gas pressure, since

the burner will not try to restart until the switch is reset.

- Safety shut-off valve (SSOV) – the first of two valves in series that automatically

opens and shuts off the fuel supply to the burner. On burners above 1200 KW,

the valve closing time is one (1) second maximum. ( Refer Multiblock).

- Vent valve – this is normally an open valve. It energizes to close. Whenever the

SSOV’s are closed, the vent valve is open, so if any gas is leaking past the first

SSOV (5), it will vent this gas to the atmosphere, so that even if the second SSOV

(7) may leak, no gas will go past this valve since there is no pressure differential

across the SSOV

- Safety shut-off valve (SSOV) – the second of two valves in series, automatically

opens and shuts off the fuel supply to the burner. On burners above 1200 KW,

the valve closing time is one (1) second maximum. This SSOV in conjunction

with the first SSOV (5) and the vent valve (6) comprise the double block and

bleed arrangement and ensure no gas leakage into the combustion chamber

during burner shutdown. ( Refer Multiblock)

- High gas pressure switch – the purpose of this safety device is to sense a high

gas pressure and shut down the burner before an unsafe condition can occur.

The high pressure is usually due to failure of the gas regulator. This switch must

be equipped with a safety lock-out requiring manual reset. This tells the

operator that the gas regulator failed since the burner will not restart until the

switch is reset. ( Refer Multiblock)

- Manual shut-off valve (MSOV) – the purpose of this valve is to allow testing of

all components of the fuel train under actual operating fuel pressure without

firing the main burner. This testing is done after any maintenance or extended

shut down to ensure all components are working properly prior to actually

firing the main burner.

- Firing rate valve – valve equipped with a modulating motor controlled by boiler

pressure (steam) or temperature (hot water) and regulates the amount of fuel to

the burner and through linkages, controls the air damper (like the cruise control

on a car), should be located as near the burner as possible.

- Test valves – the purpose of these valves is to allow testing of the SSOVs for

leakage. This test is required by ASME CSD-l and NFPA 8501 to be done on a

monthly basis.

- Drip leg – the purpose of this piping arrangement is to trap any debris or water

which may accumulate in the gas piping to prevent fouling of the fuel train

components including burner orifices.

Manufacturers also follow the latest regulations and safety standards as per the

requirements therefore, MULTIBLOCK or compact valve group used as low

pressure gas train with maximum 300 to 500 mbar permissible inlet pressure having

all necessary components inbuilt including filter, regulator and also provide many

other connection port for auto safety relief, pressure switch max and test point etc.

Reviews

There are no reviews yet.