Industrial Combustion Burner: Basics of “Industrial Burner”

Industrial Engineering involves creating products that maximize function, value, and appearance for professional manufacturers and consumers.

Gas burner, Oil burner, or Coal burner is relate to a mechanical device that burns a gas or liquid fuel in a controlled manner. An oil burner (engine) is a steam engine that uses oil as its fuel. Gas burner, a piece of metal fitted to the end of a gas pipe, with one or more small holes so arranged as to spread out the flame. An oil burner is a part that join to an oil furnace, water heater, or boiler. A Low NOx burner is a type of burner that is typically used in utility boilers to produce steam and electricity.

The burner is simply a hollow metal disk with holes punctured through its perimeter. And a gas pilot light or electric pilot sits to one side of the burner and sends a small flame or spark to ignite the oxygen-gas mixture as it flows through the holes in the burner.

Industrial Gas burner is a device to generate a flame to heat up products using a gaseous fuel as propane or natural gas. Gas burner use gas ring atomization to meet low NOx emissions. So, the fuel and combustion-supporting oxygen are supplied separately and the ration is calculated by PLC to make the combustion more complete and the efficiency increased by 2%.

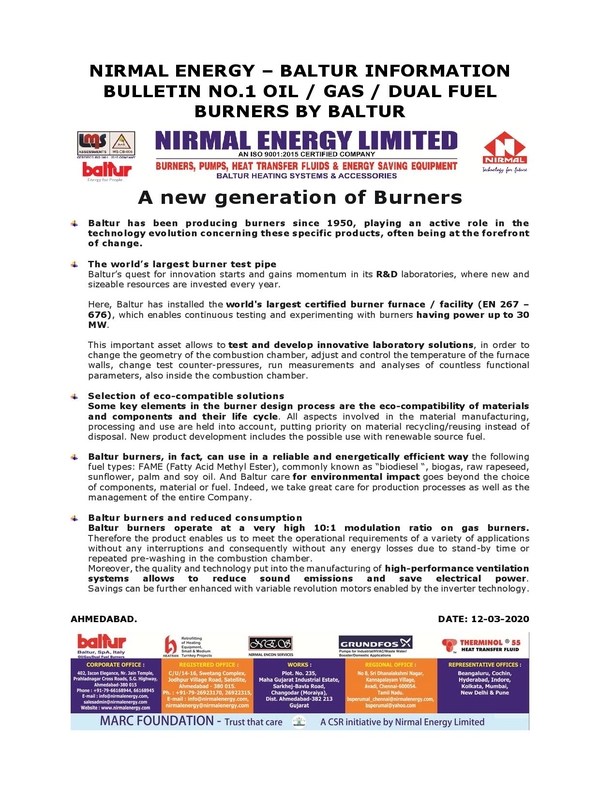

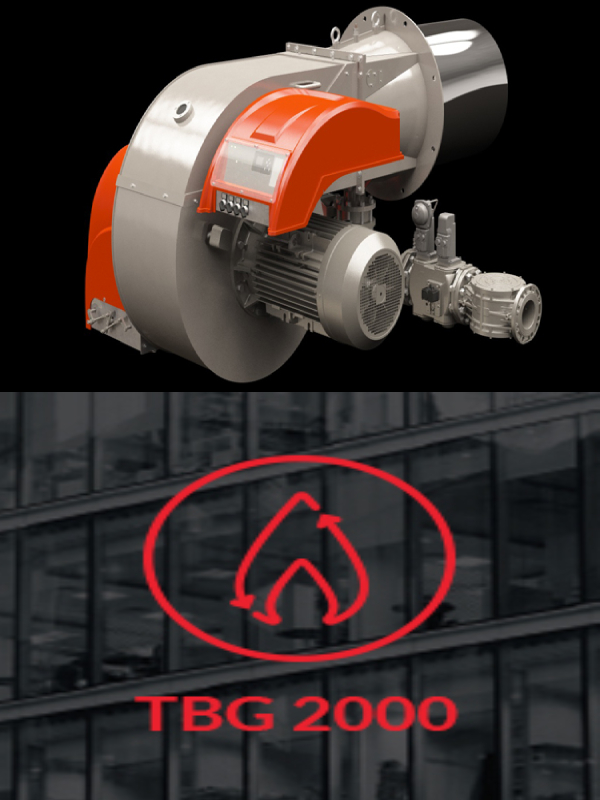

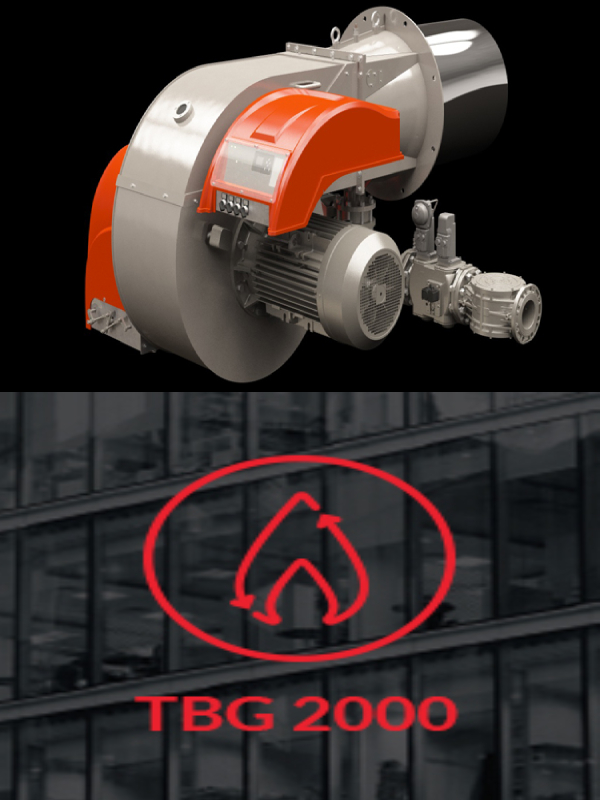

Progressive and modulating two-stage gas burners with mechanical cam.

In India, Nirmal Energy Limited, Ahmedabad is the leading provider and supplier of the Industrial Burners for their professional consumers and also for the industrial business world. They associate with Heatran Engineers to the E-commerce tepskart.com Online to Offline (O2O) platform. Tepskart provide all series of industrial burners combined with safety, environmental protection, energy saving and intelligence using fuel.